Operation and Research Activities

at the INR Accelerator Complex

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

L.V.Kravchuk, Institute for Nuclear Research of RAS, 60-th October anniversary pr. 7a, |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Abstract The

INR Accelerator Complex based on the high-intensity proton linear accelerator

is under operation. Status of the Linac and main

user facilities is given in the paper. Participation of the INR accelerator

team in some international collaborations for particle accelerator research,

development and construction is briefly described. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Introduction

The INR Accelerator Complex including a

high-intensity proton Linac, Neutron research

complex, Isotope production facility and Beam therapy complex is located in

science city Troitsk In

recent time just two high-intensity high-power proton/H-minus linacs were under operation: LANSCE (former LAMPF) at

LANL, |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

First superconducting proton linac in

the world 1.3 GeV 1.4 MW SNS Linac

at ORNL, USA is now more powerful proton linac in

the world (about 500 kW at the moment).

Construction was complete in 2006 and now the machine is in

commissioning stage to reach the design parameters as well as first

experiments at the instruments around the target are in progress. This

facility is dedicated for nanomaterials research by

neutron scattering methods.

J-PARC (JAERI/KEK, So use of the INR proton Linac in a multi-purposes complex is absolutely actual

now. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Operation of the INR

proton Linac

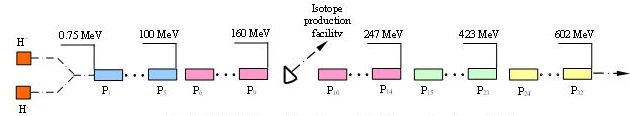

The INR proton Linac (Fig.1,2,3) consists of proton and H-minus injectors, low energy beam transport lines, 750 keV booster RFQ, 100 MeV drift tube linac DTL and 600 MeV coupled cavity linac CCL (Disk and Washer accelerating structure). There are six 198.2 MHz DTL RF stations and 31 991 MHz CCL RF stations including one reserve station per each from five Linac sectors. The detail description of the INR proton Linac is given in /1,2/. Designed, achieved and operational Linac parameters are summarized in Table 2. The Linac started

its regular operation 1993 and provided till now 79 beam runs with about

2000-2400 hours per year. It’s very important that reliability of operation

is rather good now by means of many technical and organizational improvements

– about 80-90% (percentage of a beam on user’s target from a full beam run

time). Main criteria for the Linac tuning before

start of high-intensity operation mode

(more 100 µA average current) is that the beam losses should be not more than

0.1%. Tuning procedure normally take 3-4 shifts and includes phase scan for

the DTL part and ∆t-procedure for the CCL one. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The features of accelerator operations

for main Linac

users are as follows: ∙

Isotope production – high intensity mode, average current from 70 to 120 µA.

Main problems are beam loss and operation reliability. ∙

Neutron complex – short beam pulse 0.3 - 60µs, high intensity. Problems to be

solved are beam diagnostics, phase stabilization in phase reference lines,

accelerating fields stabilization, transient processes. ∙

Proton therapy – small pulse and average current about 1 µA require a special

beam diagnostics and additional phase reference lines stabilization system. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The tasks and problems to be solved for a

further Linac operation take place because of the

machine age as well as common situation in industry. First of all a number of

klystrons on hand now limiting proton energy by 209 MeV

instead of designed 600 MeV. Many efforts have to

be done to restore the klystron production in industry or to have an

appropriate funding to design and produce it at some firm abroad (we have

offers from Toshiba and Thales). Stopping of some

RF and modulator tubes production require replacement them by available ones

with corresponding modernization of rf stations

(for instance tube GI-54A will be replaced by GI-71A, GI- 51A

by GI-57A). Some drift tubes of the DTL part should be repaired or replaced

by new ones and it’s in progress now. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The nearest tasks we are planning for

the Linac are as follows: -

completion of H-minus injector and low energy beam transport line; -

bringing a process of two beam operation (protons and H-minus

simultaneously) to routine operation; -

modernization of 160 MeV intermediate

extraction region, installation of new kiker-magnet,

providing of flexible beams distribution between experimental and isotope

production facilities; -

modernization of the DTL RF System; -

doubling of the repetition rate to 100 Hz; -

increase of proton energy as more klystrons become available. At the same time upgrade possibilities

for the INR proton Linac have to be considering

towards a modern spallation netron

source with power about 1 MW or more. It could be replacement of a few CCL

modules by superconducting cavities in the accelerator tunnel to increase

energy to about 1 GeV

/3/ or increase a beam pulse length to 1 ms or something else in dependence

from a possible budget and time scale. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Experimental Area

and the Linac Applications

Experimental Area at the exit of

the proton Linac consists of Neutron complex and

Beam therapy irradiation facility. Systems of beam formation and

transportation to targets of the experimental facilities at the moment are under modernization,

including beam diagnostics and control systems. Neutron research complex includes three

main facilities: Spallation neutron source IN-06 with

a number of multipurpose instruments, Spectrometer on neutrons slowing down

in lead LNS-100 (100 tons of pure lead) and Time of flight TOF spectrometer

RADEX. The facilities design, experimental possibilities and first results

are described in detail in /4/. Purpose of the Beam therapy complex is

oncology tumors treatment by proton beam and/or by γ irradiation. Proton beam with energy from 70 to 250 MeV in dependence from a tumor

depth is transporting to the irradiation chamber, γ irradiation is providing

by 6 MeV electron linac

SL-75-5 /5/. Low intensity of the proton beam require a special diagnostics

and control system. In nearest future there is a plan to use H-minus beam

from the INR Linac to provide a parallel work with

Neutron complex / Isotope production facility. Construction of the first turn

of the Beam therapy facility is complete in 2007 and accepted by the State

Commission. Commissioning as well as a lot of formalities to start a regular

treatment process for patients are in progress now.

The proton Linac has an interruption in the

regular accelerating structure at 160 MeV where a

beam is turning by two bending magnets to the Isotope production facility IPF

/6/. Special beam position and shape as well as a control system for precise

tuning of the beam on the target have been developed and implemented. IPF is

operating mostly for production of Sr-82 for positron-emission tomography.

Many other isotopes for medicine and industry such as Pd-103, Ge-68, Se-72,

Cu-67, Sn-117m, Ac-225 etc could be produced at the IPF in commercial scale. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

INR particle

accelerators research activity for international collaborations

INR accelerator team is widely

participating for a long time in many collaborations for the particle

accelerators development at many Laboratories abroad. For the LHC which is under commissioning at

CERN now INR successfully complete three addendums to the Since 2002 INR participates at the SNS ( Collaboration with DESY, Optimization of the Annular Coupled

Structure for J-PARC Linac (KEK/JAERI, More recent activity is INR participation

in X-ray Free Electron Laser XFEL International collaboration. INR suppose to

be responsible for design and construction of Transverse Deflecting Structure

TDS for three special diagnostics sections of the XFEL to measure

longitudinal beam profile, the slice energy spread and the slice emittance.

The list of other INR collaborations for particle accelerators

research and development is rather large (LANL, TRIUMF, ANL, FNAL, etc) and

can’t be described in detail in this paper due to a limited volume. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Conclusion

The INR proton Linac

is under operation with about 2000 hours per year. Proton energy at the

moment is 209 MeV limited by a number of klystrons

on hand, average current is till 150 µA. The main Linac

users are Neutron research complex, Isotope production facility and Beam

therapy complex.

INR is actively participating in many international particle

accelerators collaborations for R&D, construction and commissioning. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acknowledgments

This work represents collaborative efforts of the INR Accelerator Complex and Experimental Area Divisions, other divisions, groups and people. Author thanks to all of them. A partial list of people with a personal gratitude is mentioned here: V.Matveev, A.Feschenko, V.Serov, V.Paramonov, M.Grachev, B.Zhuikov, E.Koptelov, S.Akulinichev and others. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

References

[1] L.V.Kravchuk. INR proton Linac

operation and applications. Nucl. Instr. and Meth. A 562 (2006), 932-934. [2] L.V.Kravchuk.

Operation of and prospects for MMF accelerator complex. Radiation Physics and Chemistry 75 (2006), 920-922. [3] L.V.Kravchuk, P.N.Ostroumov.Upgrade Possibility of INR Proton Linac for production 3 MW beam. Particle Accel.

Conf. PAC 1999, [4] E.A.Koptelov, L.V.Kravchuk. A Neutron Complex of INR RAS – A Facility

Status Report. ICANS-XYIII, April 2007, [5] S.V.Akulinichev,

L.V.Kravchuk, V.A.Matveev.

Radiological Centre based on INR proton Linac. XIX

RUPAC, October 2004, [6] B.L.Zhuikov et al. Target irradiation facility and targetry development at 160 MeV

proton beam of [7] A.V.Feschenko

et al. Longitudinal beam parameters study in the SNS Linac.

Particle Accel. Conf. PAC 2007, [8] L.V.Kravchuk, V.V.Paramonov, V.A.Puntus. The

Cold Model of the CDS structure. XIX LINAC Conf., 1998, [9] V.V.Paramonov

et al. The PITZ booster cavity – a prototype for the ILC Positron injector Cavities. Particle Accel.

Conf. PAC 2005, [10] V.V.

Paramonov. The Coupled Cell Structures Parameters

for the Large Bore Hole Diameter. KEK report 2002-5, KEK, |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||